| Abrasive Type | Mesh Size | Hardness of Bond | Concentration | Bond Type | Depth of Super Abrasive Section |

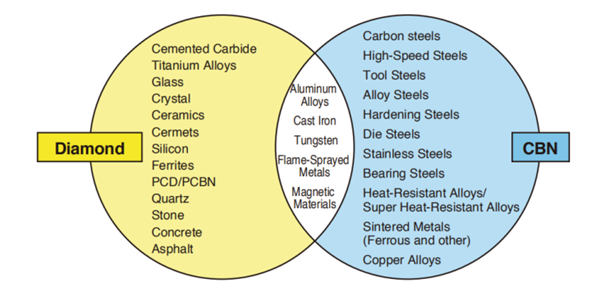

| D: Natural Diamond SD: Synthetic Diamond SDC: Coated Synthetic Diamond cBN: Cubic Boron Nitride cBNC: Coated Cubic Boron Nitride |

16 100 400 18 120 600 20 140 800 30 170 1000 40 200 1500 50 230 2000 60 270 2500 80 325 3000 |

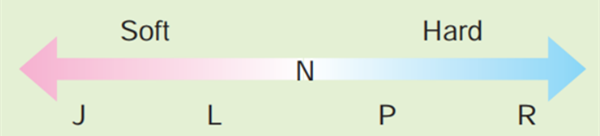

J Softer L N Medium P R Harder |

25 Lower 50 75 100 125 150 175 200 Higher |

B: Resin V: Vitrified M: Metal P: Electroplated |

1.5 mm 2.0 mm 3.0 mm 5.0 mm |

| Grit | Rough Grinding | Finish Grinding | Fine Grinding | Lapping |

| Diamond | D181 - D151 | D126 - D91 | D64 - D46 | D30 - D15 |

| CBN | B151 | B126 | B91 | B46 |

| Degree of Concentration | Grain Content ct/cm³ |

| 200 | 8.8 |

| 175 | 7.7 |

| 150 | 6.6 |

| 125 | 5.5 |

| 100 | 4.4 |

| 75 | 3.3 |

| 50 | 2.2 |

| 25 | 1.1 |

| Ra μm |

Rt μm |

Rz μm |

Roughness Class |

0.025 0.05 0.06 0.08 0.1 0.12 0.16 0.2 0.25 0.31 0.4 0.5 0.6 0.8 1.0 1.25 1.6 |

0.2 0.4 0.5 0.6 0.8 1 1.25 1.5 2 2.5 3.2 4 5 6.3 8 10 12.5 |

0.16 0.32 0.38 0.5 0.6 0.75 1 1.25 1.6 2 2.5 3.2 4 5 6.3 8 10 |

N1 N2 N3 N4 N5 N6 N7 |

| Grinding Wheels Shape | Products Code | Application |

| Flat grinding wheels | P | External grinding, internal grinding, flat grinding, centerless grinding, thread grinding, and free grinding, etc. |

| Double beveled grinding wheels | PSX | Grinding gears, tooth surfaces, single threads, and grinding end faces in the round |

| Single bevel grinding wheels | PDX | Grinding various serrations, sharpening milling cutters, reamers, gear cutters, etc. |

| Single convex grinding wheels | PDT | Mainly to solve the manufacturing difficulties of grinding wheels with large diameter and thin thickness, same as flat grinding wheels |

| Single-face concave grinding wheels | PDA | Internal grinding and surface grinding, and external grinding for larger external diameter |

| Double-sided concave grinding wheels | PSA | External grinding, tool sharpening, and also for centerless grinding wheels and guide wheels |

| Cylindrical grinding wheels | N | Vertical shaft grinding |

| Cup wheels | B | Sharpening milling cutters, reamers, reaming drills, broaches, paper cutters, etc. Also used for flat and internal grinding |

| Bowl shaped grinding wheels | BW | Sharpening milling cutters, reamers, broaches, disc-type turning tools, inserting tools, reaming drills, etc. Also can be used for grinding machine guides, etc. |

| Dish grinding wheels | D | Grinding milling cutters, reamers, broaches, shaper cutters and other tools, large size is generally used for grinding gear teeth |